Cut System S.r.l. was established in 1998 by will of Gaetano and Stefano Montaperto sharing the idea that a traditional carpenter’s shop could and should open up to new challenges in the shaping and cutting of materials other than wood. Creativity in the service of customers: our philosophy is reflected in

the variety of services and workings we carry out every day, from CNC squared

cut to hydraulic press plating, from panel and covering manufacturing to

CNC shaping, assembly of composite materials, engravings, signs, flooring

and much more.

Squared Cut

CNC Shaping

Hydraulic Press Plating

Solid tanks sculptured from cement

Squared cut

The CNC panel saw with a mouth of 3.1 metres and a depth of 3.5 metres is meant for the quick processing of plates and panels. In the processing of small lots, it often happens that manufacturers of plates need a very long time to meet customers’ and ultimate users’ requests, above all, in case the measures of pieces are not all the same.

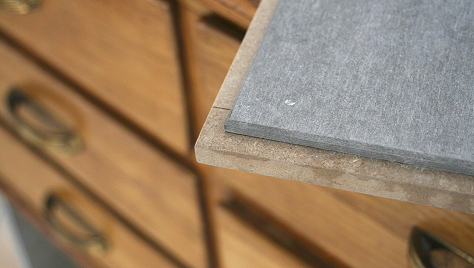

Assembly of composite materials

This activity is carried out with much care and in order to produce stratified panels for very different uses. We combine wood and fibre cement, fibre cement and Beton wood, lead and wood, lead and cement. We ennoble Medium Density Fibreboard with surfaces of any kind, often on request by the customer.

Flooring

One distinguishing element is the manufacturing and laying of cement paste floors, with pre-processed plates with both regular and pigeonhole formats. Surfaces are treated with opaque protective substances penetrating materials, or with highly resistant films. Moreover, we manufacture old wood floors or floors coupling with soundproof cement.

CNC Shaping

The CNC work centre has created great opportunities to obtain unique pieces or even serial pieces with very original shapes. Every day, constant collaboration of our technical office and architecture studios allows us to draw up and carry out more and more complex projects in terms of form and quality.

Engravings and Signs

Our workshop is conceived to produce engravings on a broad range of materials. The use of adequate construction techniques allows us to manufacture signs with big dimensions, too. Choice of materials, accuracy and the degree of perfection of the final product are always determined by our customers’ wishes and by production technique choices.

Hydraulic Press Plating

The Hydraulic press can plate panels with different sizes, up to 1200x3000 mm. Simple and ergonomic, it allows us to make material coupling through hot or cold working.

Panels

We manufacture either finished or semi-finished panels ready for laying, for anybody requiring them. Paying attention to details is the primary objective of our company.

Covering

Old wood panels made up of small boards pre-bonded on panels are one of the types of action we are specialised in. The semi-finished product is easier to deal with for the contractor who can thus use its resources in the best possible way.

Raised floors

Among widespread composite materials, we process fibre cement and phenol multilayer combinations, fibre cement and Beton Wood combinations, both of them mostly used to make raised floors.

Surface Protection Treatments

Surface treatments are carried out rigorously by hand, roller or tampon, depending on the materials used and the extension of the surface being treated.

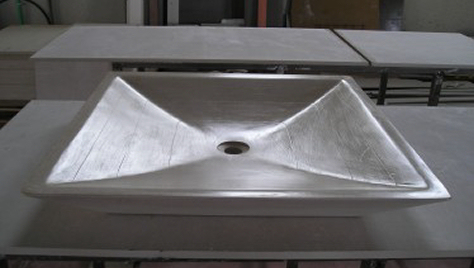

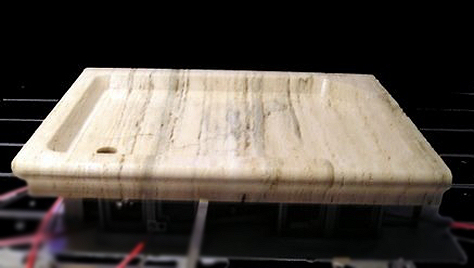

Solid tanks sculptured from cement

Eco-friendly fibre cement is one of the different materials chosen for making tanks by excavating solid cement: a material used for multiple elements, with a view to respecting our environment.

Solid tanks sculptured from solid stone

Processing stones is easy for us; designers stimulate us to study and find the best and more daring solutions.

Cut System Srl • Tel/Fax: +39 022405674 • Mail: info@cutsystem.com • Via Adige, 6 • 20099 Sesto S.Giovanni (MI) Italy • P.IVA. 12487150158